研究院

Engineered Veneer Encyclopaedia

Engineered wood veneer concept

Engineered wood veneer:scientific name reorganization of decorative materials. Using ordinary wood or fast-growing wood as raw materials, using the principle of bionics, a new type of wooden decorative material with various technical improvements in raw materials is designed by computer simulation.

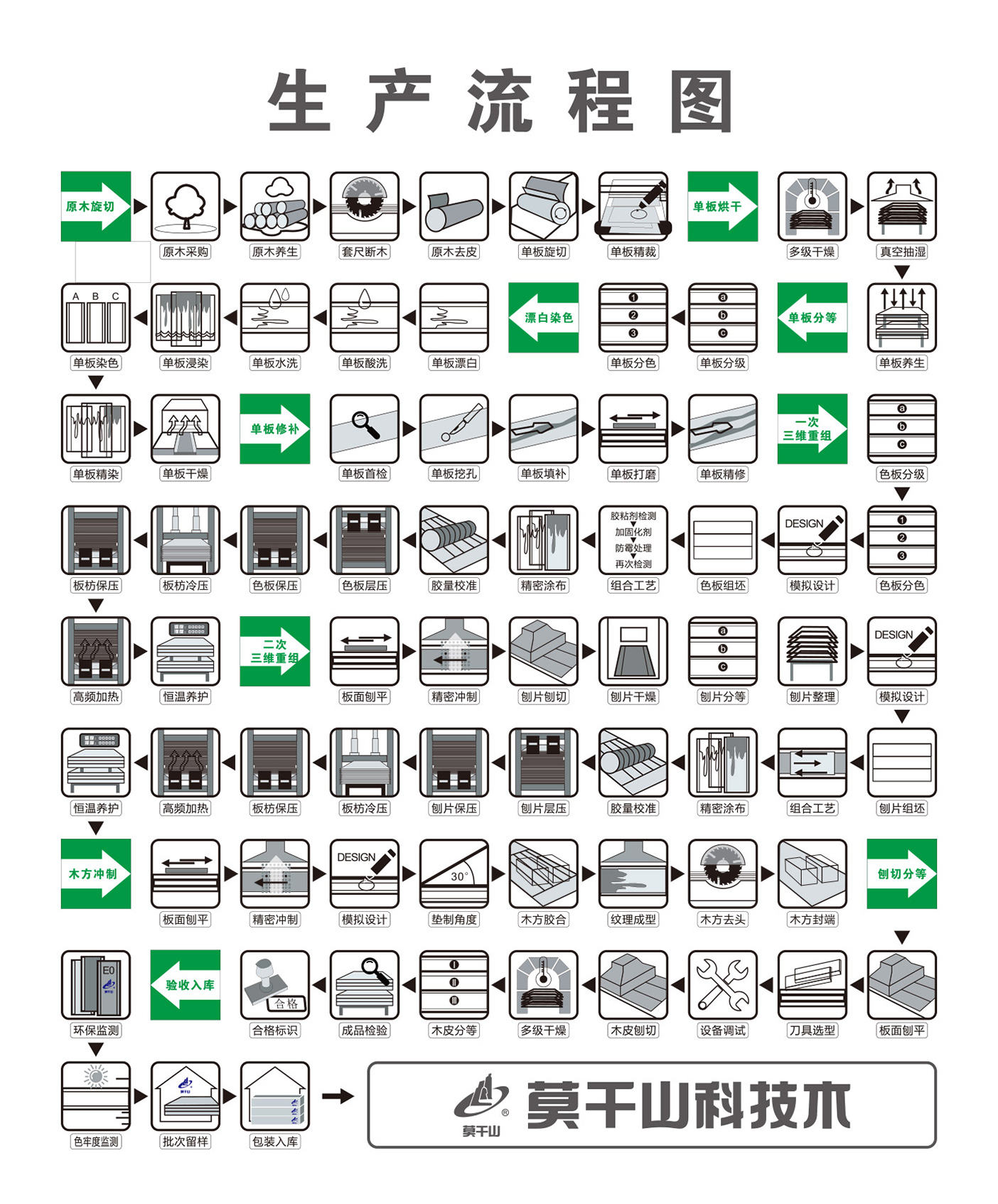

Production process of engineered wood veneer

Moganshan engineered veneer has selected imported logs from the foreign, such as African Ayous and Russian eucalyptus. Each wild log has been strictly inspected and can only enter the rotary cutting section after passing the company's stringent parameters. After that, according to the texture and process of the product, select the standard-compliant board to enter the coloring section. The coloring process adheres to visual inspection to ensure that the color is consistent with natural precious wood. Thereafter, the colored veneers are dried by an inlet dryer to control the equilibrium moisture content of the veneers within the industry standard range.

Relying on skilled manual and professional equipment, the natural defects of the colored veneers are repaired and then scientifically used to form the blanks and enter the core coating section. Finally, the technical woodwork for the finished material is cut by the imported Italian planer to ensure the superior feel and clear texture of the engineered veneer.

The value of engineered wood veneer

1.The raw material of engineered wood veneer is 100 % wood, and wood is one of the oldest materials used by human beings. It is also the most precious gift that nature has given to human beings. The four major materials in the world today are steel, cement, wood, plastic. Only wood has life and is regenerative. There are forests with wood, and wood will always coexist with humans.

2.With the improvement of living standards, human demand for natural precious wood has greatly exceeded its possession. In recent years, more and more log exporting countries have begun to protect forest resources and limit the deforestation of precious logs. Engineered wood veneer emerged in this growing contradiction, carrying the mission of replacing natural precious wood.

3.The State Forestry Administration has repeatedly stated that the use of ordinary and fast-growing wood will become the mainstream of future wood to use. Practice has proved that the development of engineered wood veneer has opened up the new avenues for the utilization of ordinary and fast-growing wood, exerting the advantages of wood renewable resources, improving the comprehensive and efficient utilization of wood, and promoting the development of wood decorative materials.

Seven advantages of engineered wood veneer PK natural wood veneer

1.It is more convenient to uses ordinary wood or take materials. The engineered wood veneer fast-growing wood as raw materials. These raw materials have the characteristics of large quantity and renewability. Generally, artificial planting can be used after growing for 8-10 years. The growth time of natural precious wood is generally 80-150 years. In addition, the amount of possession is increasingly rare, and the long-term dependence on imports has been unable to meet market demand.

2. The surface is more outstanding. The engineered wood veneer uses the principle of bionics, using landscaping techniques to create colors that natural wood does not have. The color is more abundant, the color is brighter, and at the same time overcome the natural defects of the natural wood surface, the value is higher, and can fully meet the individual decoration needs.

3. More styles. The engineered wood veneer uses computer simulation design. In addition to highly simulating the texture of natural precious wood, it can also create other more artistic textures, such as the effect of parquet art. The style is richer, the texture is clearer, and the stereoscopic effect is stronger. Greatly meet the diverse needs of decoration.

4. The performance is superior. The physical properties of the wood and the static bending strength are superior to natural wood, and it is anti-corrosion, anti-mite, moisture-proof and easy to produce. It can be produced into different sizes according to different needs, overcoming the limitations of natural wood.

5. Use more efficiently. The engineered wood veneer has no natural defects of natural wood such as wormholes, thrift, and discoloration. The texture and color have certain regularity, which greatly avoids the

splicing troubles caused by the difference of texture and color of natural wood, and greatly improves the usage rate of decoration process.

6.More widely used. The engineered wood veneer is made of ordinary wood and has been landscaping to become a high-duality wood with the characteristics of texture, pattern and color of natural precious wood. Compared with natural precious wood, there is no grade of natural wood, and it is more cost-effective. It is widely used in furniture, hotel decoration,fooring, doors and windows, handicrafts, sporting goods and other fields.

7.The mission is greater. The engineered veneer uses natural wood as raw material. In the production process, it does not change the basic properties of natural wood. It completely retains the natural properties of

wood insulation, insulation, temperature regulation and humidity control, which meets people's great demand to the affect and dosage of decoration,At the same time, engineered wood veneer shoulders the

mission of a global sustainable green development strategy to protect natural and precious forest resources.